How Is 5s/6s Utilized During Lean Improvement Activities

See the answer See the answer See the answer done loading. Evaluate 5S effectiveness and consistently improve.

Lean Thinking And Methods 5s Us Epa

6S is a modification of the 5Ss but adds safety as the sixth S.

. 6s uses these five pillars plus an added pillar for safety. 6S otherwise known as 5S Safety is a system that aims to promote and sustain a high level of productivity and safety throughout a workspace. Organize what remains in the work area.

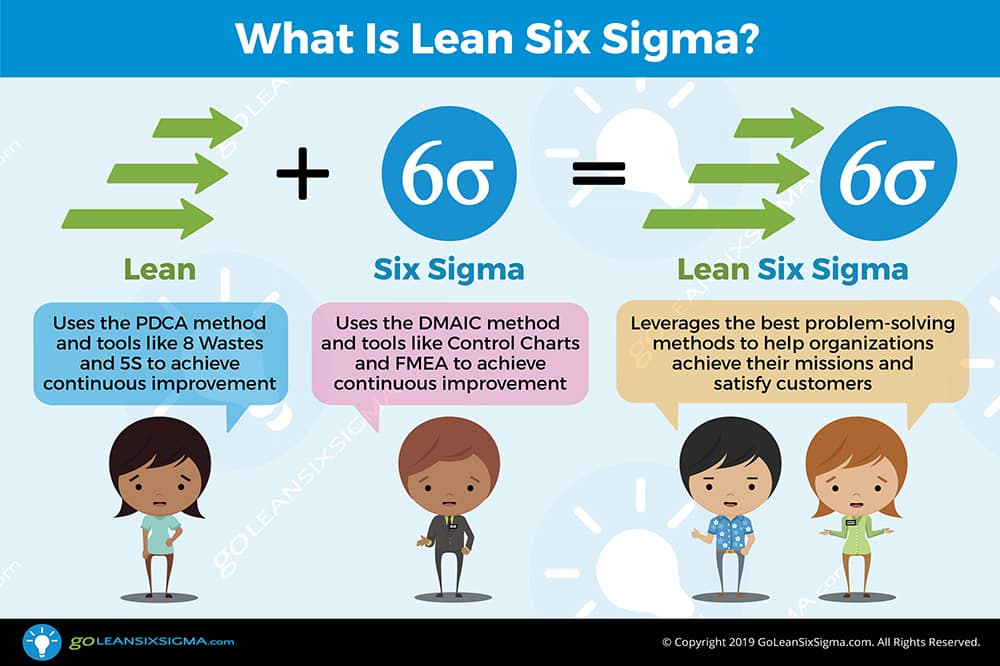

Kaizen focuses on eliminating waste improving productivity and achieving sustained continual improvement in targeted activities and processes of an organization. This problem has been solved. While adhering to the 5S principle of Sort Set in order Shine Standardize and Sustain the 6S method adds the concept of Safety.

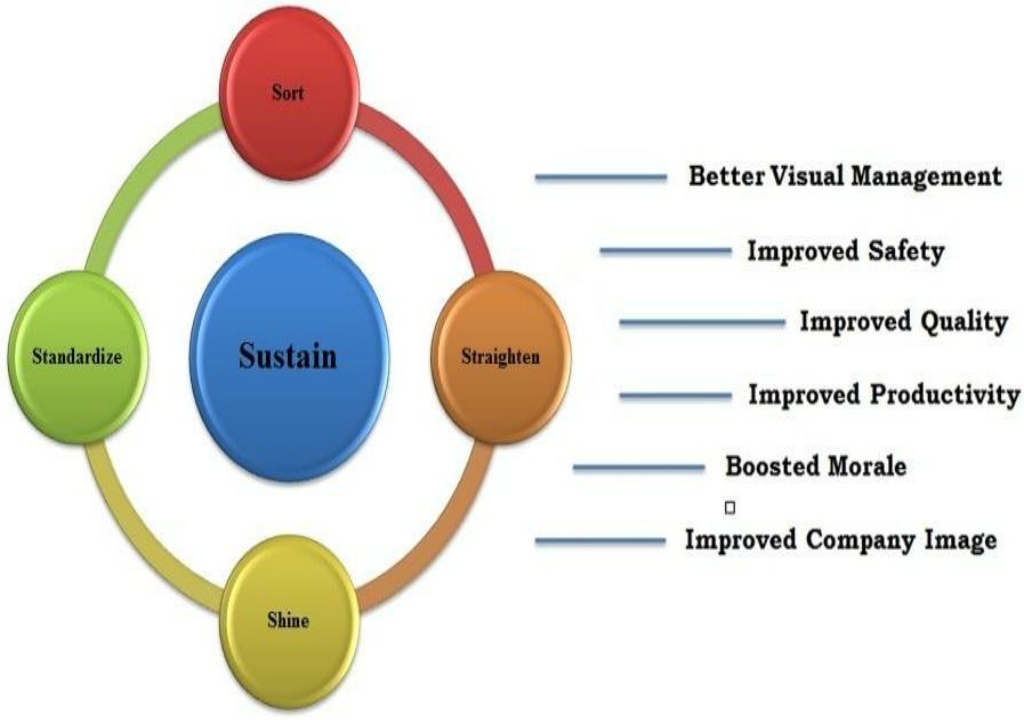

The 5s pillars sort set in order shine standardize and sustain provide a methodology for organizing cleaning developing and sustaining a productive work environment. Specifically better organization and management of information flow allows. 6S is modeled after the 5S process improvement system designed to reduce waste and optimize productivity in the workplace by.

Set in order Organize. How is 5S6S utilized during Lean improvement activities. Shine Clean and solve.

6S is a method used to create and maintain a clean orderly and safe work environment. Creating and maintaining organization and orderliness Using visual cues to achieve more consistent operational results. Do you have safety as an item in your TPM programs six sigma projects kaizen events suggestion programs quality circles SMED initiatives 5 whys fishbone diagrams other.

Jamming it into 5S to make it 6S makes safety seem like a program which it should not be. Acknowledge reward powerful efforts. Kaizen or rapid improvement processes often is considered to be the building block of all lean production methods.

Periodic facility management engagement is needed to check that the first four Ss are implemented perfectly. Lean and Environment Toolkit January 2006 Slide 4 4 What is 6S. Clean and inspect the work area.

It promotes activities of continuous improvement in. Sort Get rid of it. 6s encourages workers to improve the physical setting of their work and teaches them to reduce waste unplanned.

Define value from customer perspective Identify the value stream Eliminate waste Flow the process Pull the product Engage involve empower employees Pursue to perfection. Includes Free Bonus Info. Office Efficiency Quality Progress The 5S lean method is often used in manufacturing but it can be adapted for office settings to make information workflows more efficient.

Ad Keep Workplaces Safe Productive. It should be embedded in every decision and the everyday life of an organization. D Once the Lean Improvement team completes analysis of the Current State Value Stream Map their focus becomes documenting process Takt time and C Safety Many company uses 5S The Sort Set Shine Standardize and Sustain but others have added another S which is the Safety now base on the given example those particular area suits the last S of the 6s which is the.

Of course this should be done in a safe manner but thats not the point. All the activities an organization must complete to generate a product information or service. How is 5s 6s utilized during lean improvement activities.

Implementation was done by a standardized process tested in a pilot area that is. The purpose of 5S is to be more lean more efficient more productive eliminate waste. Results show that the 5S framework is an effective and simple model for process design and improvement.

The 5Ss are sort straighten scrub standardize and sustain. Highest quality lowest cost shortest lead time by continually eliminating muda. Commitment dedication devotion sincerity are required in the implementation of 5S on daily basis.

How is 5s6s utilized during Lean improvement activities. 5S is a tool like any other. This paper proposes an expansion of the Lean 5S methodology which includes the concept of Safety-Security as 6S.

Learn How 5S Can Improve Your Facility. Lean production is founded on the idea of kaizen. Everything You Need To Succeed With 5S.

Guides organizations to create and maintain an organized clean and safe work environment as a foundation for achieving Lean Which Lean tool is useful in mapping the flow of the information or. Separate what is needed in the work area from what is not. Guides organizations to create and maintain an organized clean and safe work environments as a foundation for achieving lean.

Overall 6S is a process for creating and maintaining an organized clean high performance workplace. Ron Pereira managing partner for online training company Gemba Academy called the debate a hot topic for those in the lean manufacturing arena.

Benefits Of 5s Lean Visual Management Lean Process Visual Management Process Improvement Lean Process Improvement

I M Like A 1 All The Way Across The Board Oh God Business Management Management Infographic Business Process Management

The Ultimate Guide To 5s Tulip

5s Lean Products Supplies Resources Visual Workplace Inc

Explaining The 5s Methodology Change Management Lean Six Sigma Lean Process Improvement

Continuous Improvement A Kaizen Model Creative Safety Supply

5s 7s A Must Require For Lean Transformation

In 5s There Are Actually 6 Steps Check Out This Overview Of The 5s System Lean Six Sigma Visual Management Lean Sigma

Key Benefits Of 5s Process Implementation Lean And Operational Excellence Support For Calgary Edmonton And Alberta Companies

Everything About 5s In Lean Manufacturing Lucidchart Blog

Lean Six Sigma Process Improvement Goleansixsigma Com

Top 50 Lean Tools Comprehensive List For Lean Manufacturing And Service

Applying 5s In The Manufacturing Industry Lean Production

Key Benefits Of 5s Process Implementation Lean And Operational Excellence Support For Calgary Edmonton And Alberta Companies

Comments

Post a Comment